|

|

|

(4)

Intermittent Boiler Blowoff, Hydronic S.R.V's, and other Process Blowdowns

Blowdown Separators are the modern and efficient way of handling boiler intermittent blowdown. Separators have also been used for hydronic safety relief valve discharges, deaerator overflows, autoclave draining, and other high flow pressurized condensate to drain applications. The smaller diameter takes up less space then a traditional blowoff tank while providing an efficient separation of flash steam and condensate.

|

|

|

|

|

|

|

Traditional Style Blowoff Tank Sized to National Board

Blowoff tanks are the traditional way of handling boiler intermittent blowdown. These style of tanks are normally recommended for utility and other larger steam process boiler applications. The tank is sized to collect each blowdown while allowing radiant heat to escape. The cooled blowdown in the tank then mixes with each new blowdown. Other applications require additional flows into the tank. This can include continuous blowdown, deaerator overflows, and other waste condensate flows.

|

|

|

|

|

|

|

Boiler Water Cooling Under Pressure for Safe Accurate Samples

When boiler water samples are taken without being cooled under pressure as much as 20% of the sample can flash to steam leaving a greater concentration of solids in the boiler water and inaccurate readings when making your analysis. The purpose of the SC325 sample cooler is to cool samples under pressure so accurate sampling can be made.

|

|

|

|

|

|

|

(3)

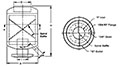

Boiler Treatment Feeders for Adding Boiler Water Chemicals:

Three models of chemical feeders are available a SF-250 Shot Feeder, AF 251 Adjustable Feeder, and IF 252 Inline Feeder. All are welded carbon steel construction. ASME Code designed and stamped for 250 psig at 450 deg. F. Each comes with the necessary accessories for that model. They feature 14" heads welded together to create a 8" wide vessel which has a capacity of 2.5 Gallons. The exterior includes a shop primer finish.

|

|

|

|

|

|

|

Flash Tanks for Handling Condensate and Flash Steam Recovery:

Penn Flash Separators use a tangential inlet and cyclonic action to instantly separate steam and condensate. Our Flash Separators are smaller in size and more efficient then traditional flash tanks. Because of the unique smaller size they are less expensive then traditional flash tanks. The clean steam can be returned to a lower pressure use saving valuable BTU's and make-up water return on investment can be in a matter of weeks. Easy to use flash steam and selector charts assure proper sizing of a Flash Separator for your condensate requirements.

|

|

|

|

|

|

|

(28)

Inline Centrifugal Entrainment Separators for Steam, Air, and Other Gases:

Penn Inline Separators create a centrifugal spinning action that separates out liquid entrainment droplets in steam, air, or other gases. Each are Inline type designed to fit in existing piping.

|

|

|

|

|

|

|

(16)

Clean and Quiet Release of Steam, Air, & other Gases Vented to Atmosphere.

Entrained water, oil and dirt in exhaust steam, air or gas vented to atmosphere can cause damage, unsightly icing and dirt accumulation on roofs, buildings and surroundings. A Penn Cyclone Exhaust Head placed on the end of the vent line creates a cyclone spinning action that separates entrainment and directs it to a drain. The large diameter outlet and internal baffles help minimize exhaust noise while protecting the line from the entry of rain and snow.

|

|

|

|

|

|

|

(28)

Muffler to Quite Noise From High Velocity Steam and Air Atmospheric Venting.

When steam, air, and other gases are vented to atmosphere at high velocities noise is created. Typically the higher the velocity the louder the noise level. Penn makes two models of Exhaust Silencers to reduce noise levels. Our "SP" full sized unit provides maximum noise reductions of 34-46 dB(A) or choose our SP-S short version that provides noise reductions of 24-30 dB(A). A wide range of sizes 2" through 24" are available.

|

|

|

|

|

|

|

(61)

High Efficiency Entrainment Separators for Process, Vacuum, and Environmental Applications.

Mist Separators are a ASME Code pressure vessel body with a mesh pad "Mist Eliminator" separating element located in the center of the unit. The flow is slowed as it travels upward through the element. The small droplets collect on the element until they are large enough to fall free of the flowing steam, air or gas flow. Our original designed was for low pressure boilers. Now the Mist Separator is available in special individually designed units for most liquid from gas applications.

|

|

|

|

|

|

|

(10)

Continuous Blowdown Heat Recovery System for Boiler Surface Blowdown.

Most boiler manufacturers and water treatment companies recommend boiler water TDS be maintained at certain levels. The purpose of continuous blowdown is to continuously take boiler water from 4"-6" under the surface where the TDS is at its highest concentration so that it can be replaced with fresh water. While continuous blowdown is the best way in controlling these solids in the boiler the heat lost to drain over time can be tremendous. Penn Continuous Blowdown Heat Recovery Systems can recover 90% or more of this heat normally lost. Two stages provide the heat recovery.

|

|

|

|

|

|

|

Most boiler manufacturers and water treatment companies recommend boiler water TDS be maintained at certain levels. The purpose of continuous blowdown is to continuously take boiler water from 4"-6" under the surface where the TDS is at its highest concentration so that it can be replaced with fresh water. While continuous blowdown is the best way in controlling these solids in the boiler the heat lost to drain over time can be a tremendous. Penn Crossover or Shell & Tube Continuous Blowdown Heat Recovery Systems can recover up to 95% of this heat normally lost. Two stages provide the recovery. The first stage uses a Penn Flash Separator where the high pressure condensate flashes to a low pressure steam use such as a feedwater heater or ...

|